View the Digital Experience Video to learn about the various features of AIRTEK and understand how its technology reinvents the landscape of aircraft seating.

The future of lightweight

sustainable aircraft seats

Innovation to support a greener future for the air transport industry

AIRTEK is a UK government funded project aimed at revolutionising the design of aircraft seating to deliver next generation products for a more sustainable future. In partnership with the UK’s Aerospace Technology Institute, the programme brings together aviation know-how from JPA Design, Formula 1 material technologies from Williams Advanced Engineering and aerospace certification experience from SWS Certification. Through a collective commitment to driving down the weight and emissions of tomorrow’s commercial aircraft, the project partners seek to deliver market-ready solutions for more sustainable flight.

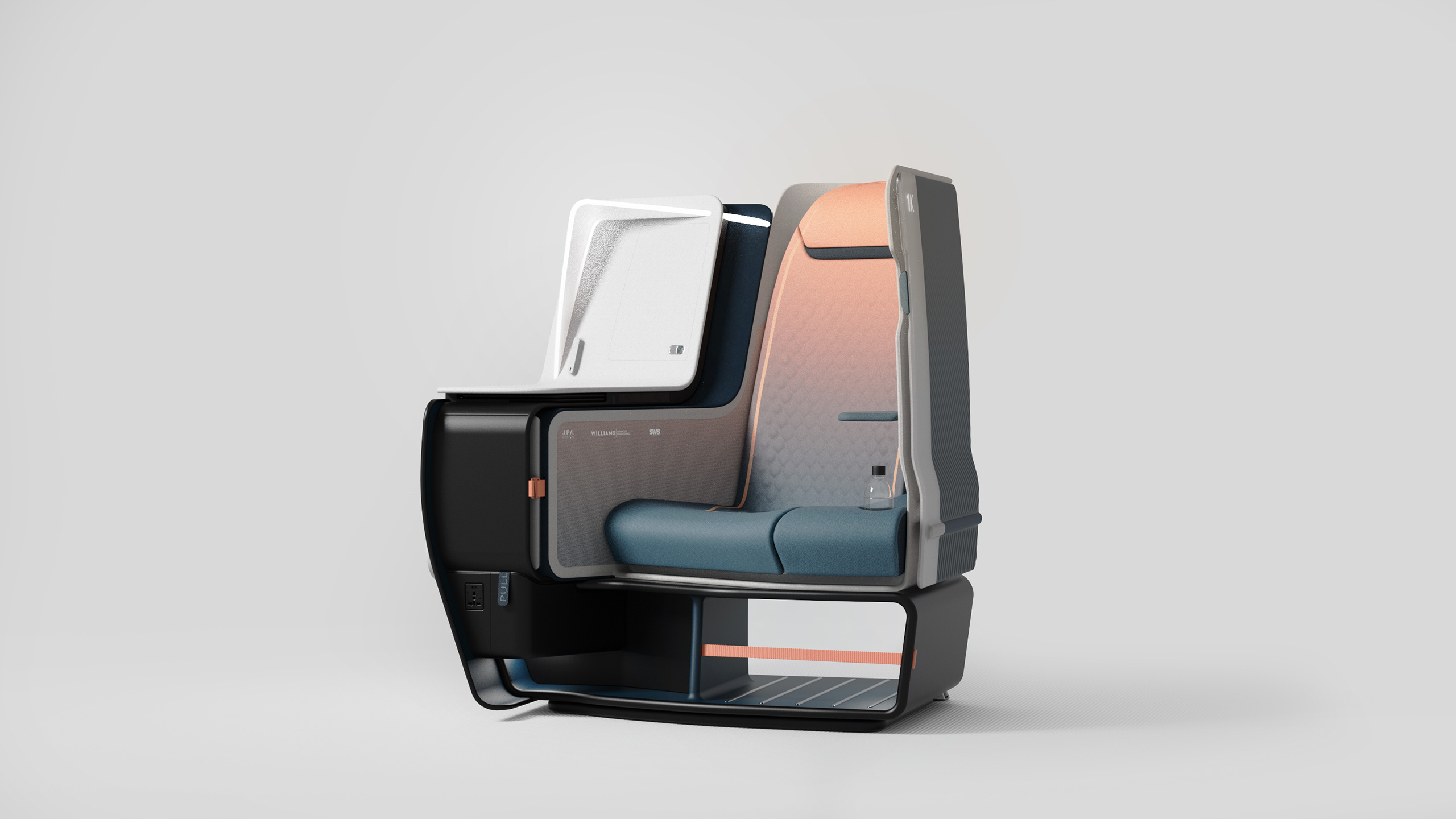

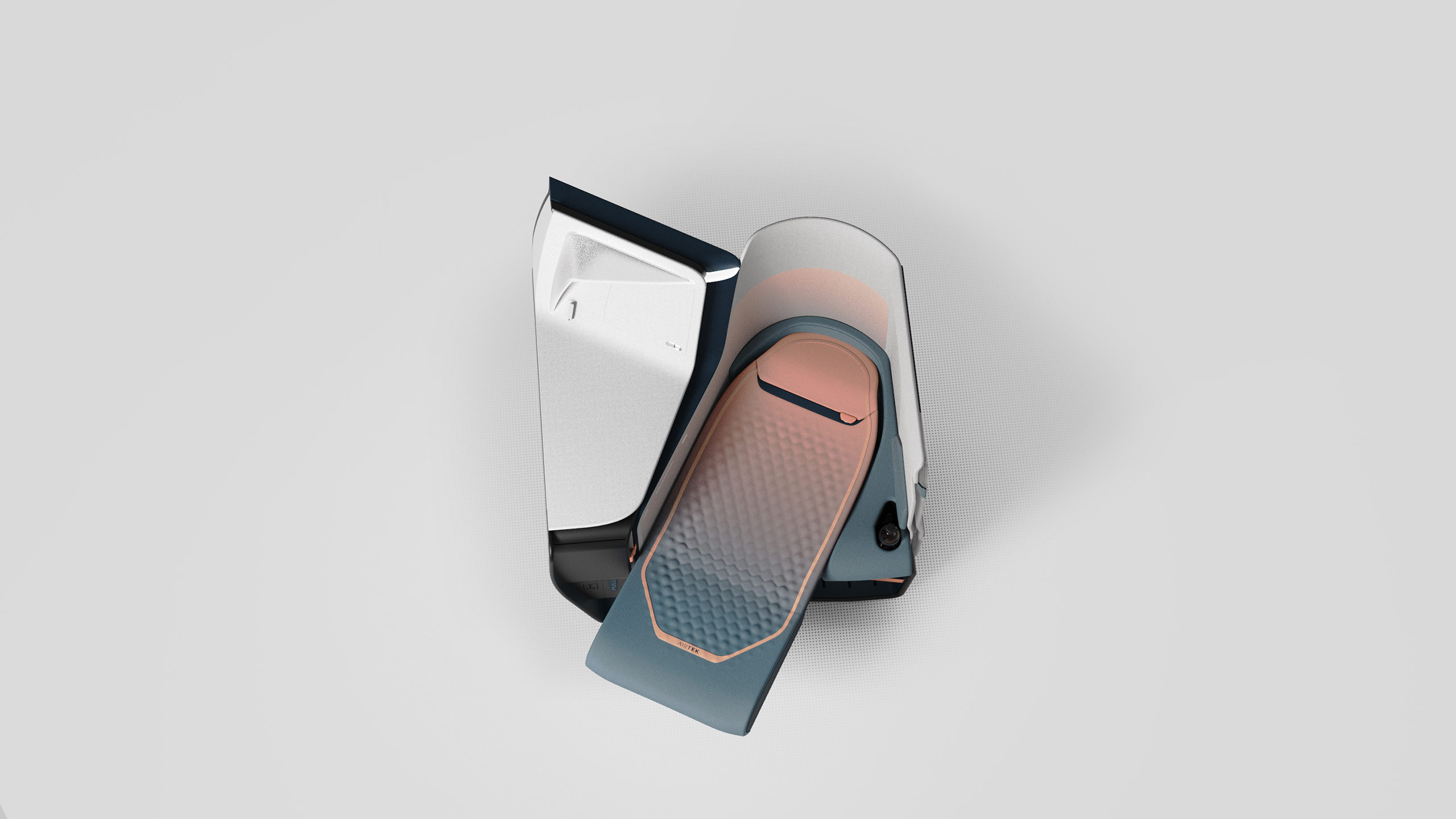

AIRTEK SEAT

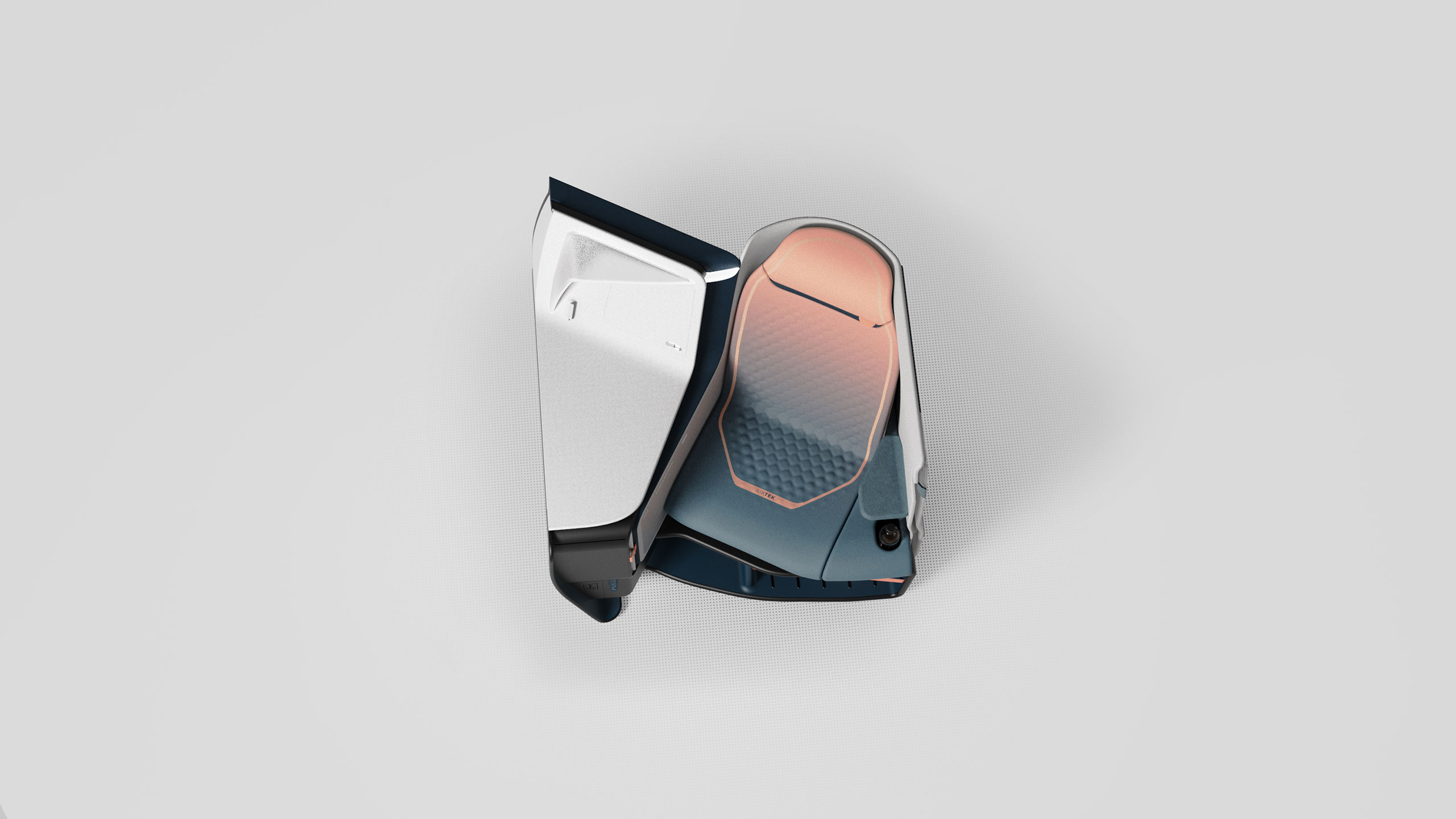

Increased customer comfort

Less structure gives more living space and more personal storage

Improved sustainability

Lightest business class seat – ever. Lower weight reduces fuel burn and carbon emissions

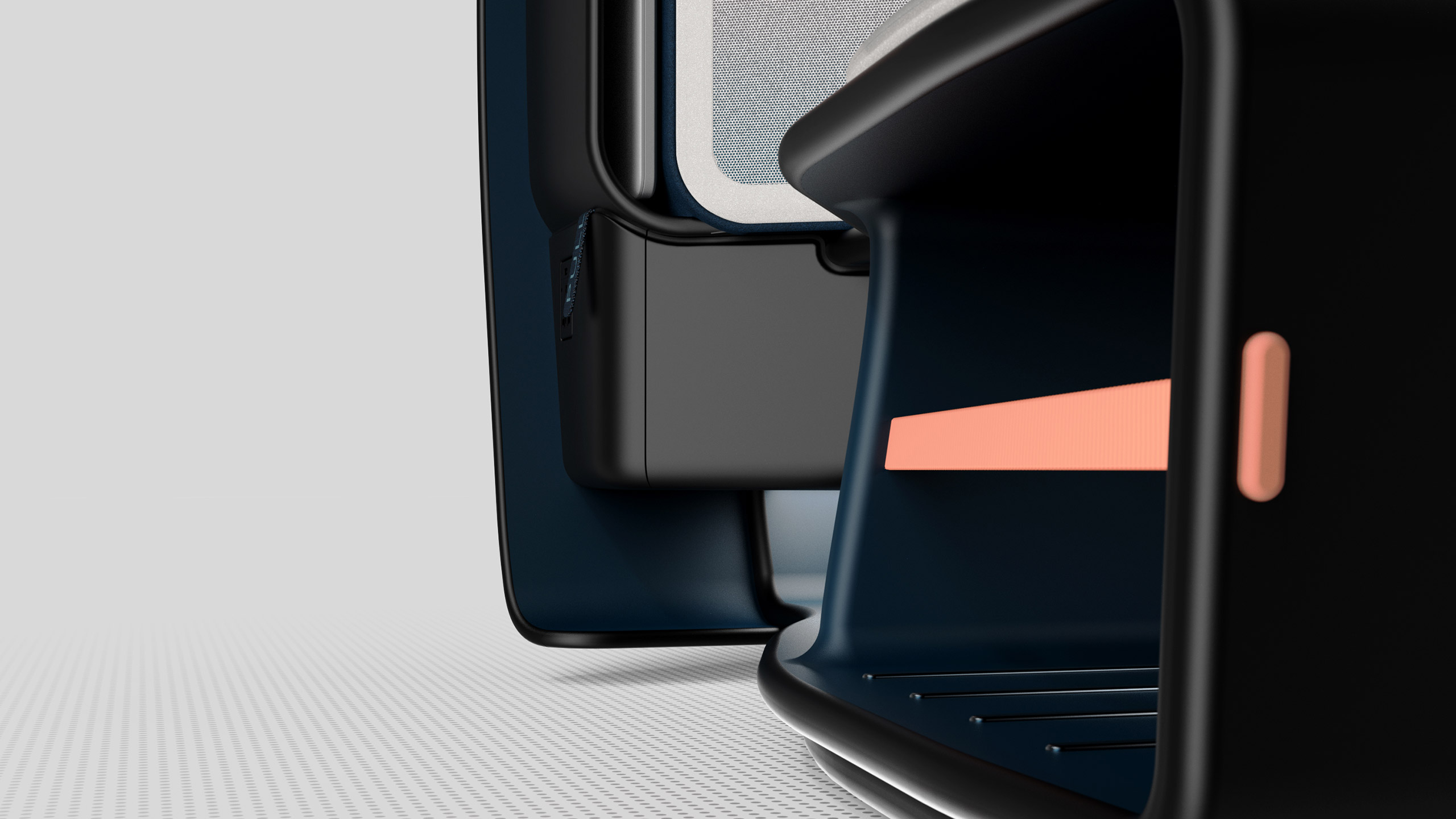

Increased reliability

Less metallic structure and fewer moving parts means less maintenance

Reduced total cost of ownership

Fewer parts and less weight mean less fuel burn and maintenance

Improved production

Reduced part count makes production efficient and robust

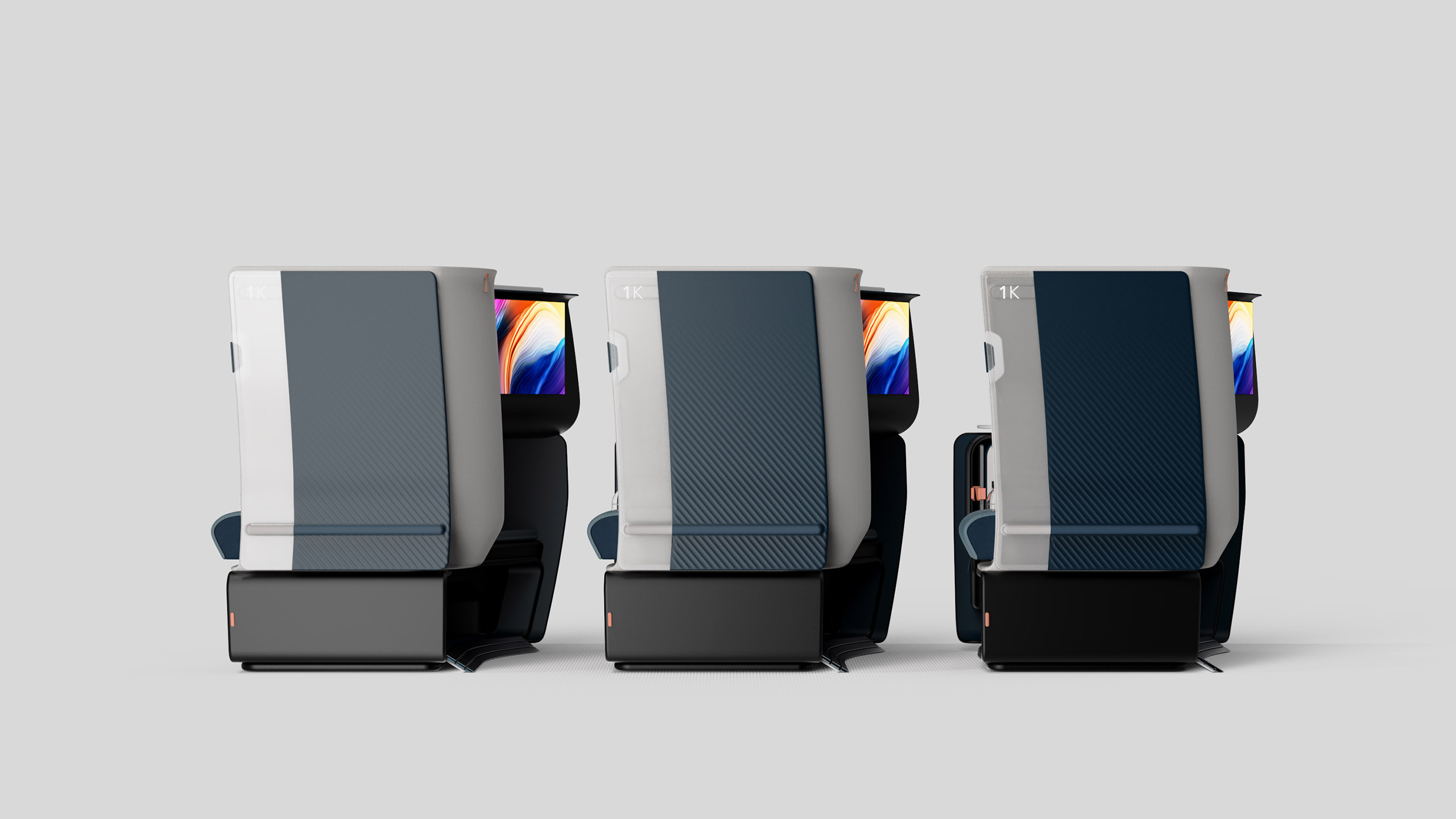

Product Specifications

| Narrow body | Wide body | |

|---|---|---|

| Layout: | Reverse herringbone 45° | Reverse herringbone 30° |

| Seat width: | 21” | 21” |

| Seat pitch: | 38” | 45” |

| Bed length: | 78.9” | 80” |

| Bed width: | 27 – 21” | 30 – 21” |

| Shell height: | 48.7” | 48.7” |

| Monitor size: | 20” | 20” |